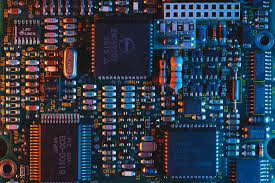

printed circuit board trace routing

Impedance matching in printed circuit board (PCB) trace routing is a critical aspect of signal integrity design, particularly in high-speed digital and high-frequency analog circuits. Impedance matching refers to the process of adjusting the electrical impedance of a signal trace to match the impedance of the connected components or transmission medium, minimizing signal reflections and maximizing signal integrity. Proper impedance matching ensures efficient signal transmission, reduces signal distortion, and enhances the overall performance and reliability of electronic devices.

One common technique for performing impedance matching in PCB trace routing is controlling trace width and thickness to achieve the desired characteristic impedance. The characteristic impedance of a transmission line is determined by the dimensions and dielectric properties of the PCB substrate and trace geometry. Designers can use impedance calculation formulas or impedance calculators to determine the appropriate trace width and thickness required to achieve the desired impedance, typically 50 or 75 ohms for most high-speed digital signals.

Moreover, designers can use controlled impedance routing techniques to maintain consistent impedance along signal traces, minimizing impedance variations and signal reflections. Controlled impedance routing involves fabricating PCB traces with precise dimensions and impedance profiles, typically achieved through techniques such as microstrip or stripline routing on specific layer stacks. By carefully controlling trace geometry, dielectric thickness, and copper thickness, designers can achieve accurate impedance matching and ensure reliable signal transmission across the printed circuit board.

how do you perform impedance matching in printed circuit board trace routing?

Furthermore, impedance matching can be achieved using impedance discontinuities such as stubs, vias, or impedance transformers. Stub matching involves adding short, controlled-length stubs to the signal trace at specific intervals to adjust the effective electrical length and impedance of the trace. Vias can also be used to transition between different impedance traces or layers, providing impedance continuity and minimizing signal reflections. Additionally, impedance transformers such as tapered traces or transmission line transitions can be used to match impedance between traces with different characteristic impedances.

Additionally, designers can use termination techniques to improve impedance matching and reduce signal reflections at the end of transmission lines. Termination resistors or termination networks can be added to the receiving end of signal traces to absorb reflected signals and match the impedance of the load, preventing signal reflections from propagating back along the transmission line. Common termination techniques include series termination, parallel termination, and termination using termination resistors or termination networks.

Moreover, signal routing topologies such as differential signaling can help achieve impedance matching and improve signal integrity in high-speed digital circuits. Differential signaling involves transmitting signals as a pair of complementary signals with equal and opposite voltages, which helps reduce electromagnetic interference (EMI) and improves noise immunity. By properly routing and matching the impedance of differential signal pairs, designers can achieve better signal integrity and minimize signal distortion in high-speed data transmission.

Furthermore, simulation and modeling tools can be used to analyze and optimize impedance matching in PCB trace routing. Advanced simulation software, such as electromagnetic field solvers and signal integrity analysis tools, allows designers to model the electrical characteristics of PCB traces and predict signal behavior under various conditions. By simulating impedance matching techniques and evaluating their impact on signal integrity, designers can identify optimal routing configurations and ensure reliable signal transmission across the PCB.

In conclusion, impedance matching in printed circuit board (PCB) trace routing is essential for ensuring efficient signal transmission, minimizing signal reflections, and maximizing signal integrity in electronic devices. By controlling trace geometry, using controlled impedance routing techniques, employing impedance discontinuities, implementing termination techniques, utilizing differential signaling, and leveraging simulation tools, designers can achieve accurate impedance matching and enhance the performance and reliability of PCBs in high-speed digital and high-frequency analog applications. Through careful planning, design optimization, and adherence to best practices in impedance matching, designers can ensure superior signal integrity and optimal operation of electronic devices in a wide range of applications.