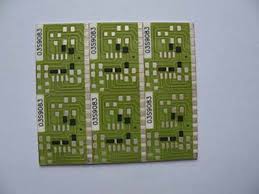

Ceramic Printed Circuit Boards Be Recycled

While the word “ceramic” might bring to mind pottery baking in a kiln, this durable material is an exceptional performer when it comes to printed circuit boards. Ceramic PCBs have impressive thermal, mechanical, and chemical resistance properties that make them ideal for a wide variety of applications.

They can also be made to order with precise customization based on application-specific requirements, such as substrate material, layer configuration, trace layout, and component placement. This allows engineers to optimize the performance of a given product, increasing its efficiency and reliability while reducing its overall cost.

ceramic printed circuit board can also be a smarter choice than traditional PCBs for many applications, particularly those that need to operate in harsh environments. Their thermal and mechanical properties help them to withstand high temperatures without warping or breaking down, ensuring that the electronic components can function smoothly and safely. Furthermore, their ability to withstand a wide range of chemicals makes them a good choice for applications where exposure to corrosive substances may occur.

Can Ceramic Printed Circuit Boards Be Recycled?

A ceramic PCB’s inherent high thermal conductivity is another advantage that allows it to do a remarkable job of managing heat flow throughout the board. This keeps the electrical signals and components cool, preventing overheating and improving device lifespans. They are also more resistant to mechanical stress and vibration, which can reduce the risk of failure and extend the operating life of a device. Their excellent chemical and environmental resistance can also help to prevent damage from exposure to corrosive materials, such as sulfides.

Moreover, ceramics have a relatively low coefficient of thermal expansion (CTE), which makes them a better choice for applications where temperature changes could cause dimensional fluctuations and lead to the formation of cracks. They are similar to silicon in this regard, which can be beneficial for a circuit board’s durability and longevity.

Ceramic PCBs can also provide excellent electromagnetic interference and electromagnetic compatibility (EMI/EMC) performance, protecting the integrity of electronic signals and minimizing signal loss. This is a vital feature for the modern world of high-speed data and communication, especially in applications like wireless technology and aerospace devices.

Finally, ceramic PCBs can be recycled using a process that separates and recycles copper from the other components of the board. This is a highly complex and time-consuming task, but it can be done in a way that minimizes the environmental impact of the recycling process and maximizes returns. The best place to start is with the tin and lead solder dross from the hot air leveling process, which can be separated by heating it in a reverberatory furnace, deslagging it, and melting it down with sulfur to recover copper metal. This can then be used to manufacture new ceramic circuit boards or other products.